X-ray Sources 101: Anatomy of an X-ray Tube

What are the major parts of an X-ray tube?

X-ray tubes come in many different shapes, sizes, materials, and configurations depending on their ultimate end application, but all X-ray tubes share some common anatomy. In the analysis space, there are tubes specialized for X-ray Fluorescence, X-ray Diffraction, and online process control of all kinds. There are also tubes for many different kinds of imaging applications, from checking bond wires inside electronic components to looking at recently biopsied tissue samples to verifying fill levels in opaque canned and bottled goods. Every tube MXR makes is tailored to your specific end application, but the building blocks of the tubes are universal. In this edition of X-ray Sources 101, we’ll look at the parts of an X-ray tube that you’ll find, no matter the application.

X-ray Tube Parts: Cathode

All X-ray tubes need a source of electrons, and this can be found on the cathode side of the tube. Cathode side configuration will vary from tube to tube, but will always include an electron source and some sort of focusing elements. In the case of the most simple filament tube, the cathode side consists of just a filament and passive focusing cup at the ground potential. At the other extreme, the cathode may contain a cathode emitter, beam shields, and several focusing grids at various voltages to assist with electron extraction and beam shaping.

X-ray Tube Parts: Anode

Just as all X-ray tubes need an electron source, they also need a target for those electrons to hit. Most MXR sources use reflection-style anodes, which are a combination of a thin target material disk and copper heatsink. There are a variety of different target materials that produce different X-ray spectra (we’ll cover the topic in a later issue), but in principle X-rays are created in the same way regardless of target material (that mechanism, too, will be the topic of a later issue). The target disk is generally bonded to a large piece of copper which acts to remove the heat generated in the spot and direct it away from the target material.

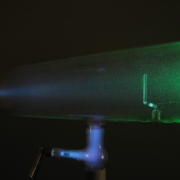

X-ray Tube Parts: Window

A window is where the useful X-rays exit the tube. An individual X-ray is emitted in a random direction based on the interaction between the electron beam and the target material electron that it collides with. X-rays are generated in a spherical pattern around the target, with half of the sphere being directed back into the target material, and half of the sphere extending outwards from the target material. Some amount of the X-rays generated are directed towards the X-ray tube’s window. Beryllium is a desirable window material due to its position as the lowest Z metal, allowing for a tight vacuum seal, mechanical robustness, and minimal X-ray attenuation. In some cases other materials may be used where the attenuation of low energy flux due to the window is not important.

About Micro X-Ray

Micro X-Ray designs and manufactures X-ray tubes and X-ray sources entirely in our California facility. Our X-ray sources provide best-in-class performance for a wide variety of applications. We offer packaged tubes in various configurations and geometries, with customizable power levels, target materials, spot geometries, integrated shielding, and integrated cooling options tailored to your application and environment. Whether you are a large OEM, system integrator, repair facility, or university, we welcome the opportunity to discuss your specific X-ray tube requirements.

2020 Micro X-Ray

2020 Micro X-Ray