Operational Tips: Why Should I Care About Filament Current?

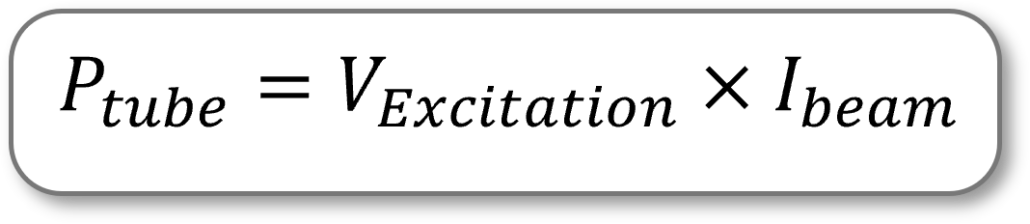

When you’re using an X-ray tube, it’s important to set the right parameters. First, there’s the excitation voltage of the tube, usually expressed in kV. Next, there’s the beam current of the tube, usually expressed in mA. If you multiply the two together, you can get the X-ray tube’s power. (Need a refresher? Check out this article)

What is Filament Current, Anyway?

So that’s the excitation voltage and beam current, but most high voltage power supplies also have a filament current limit and filament current pre-heat. What are those, and how do they relate to the beam?

One trick: because kV is V*10^3, mA is A*10^-3, and power is P=V*A you can easily calculate power in your head because 10^3*10^-3 reduces to exactly 1, so the power of the tube is just the integer kV value times the integer mA value. A tube running at 50kV and 1mA, therefore, runs at 50*1=50W. A tube running at 25kV and 0.5mA is running at 25*0.5=12.5W.

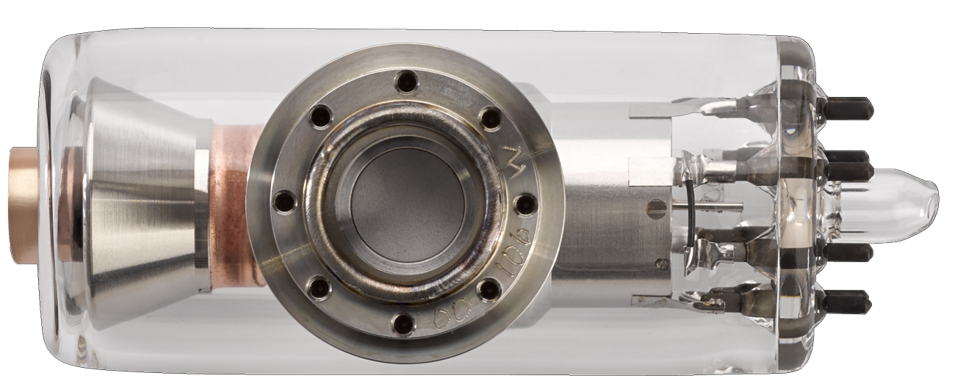

To answer this question, we need to remember how X-ray tubes work. The beam isn’t controlled directly, but rather it’s generated when electrons at (or near) the ground potential see a high potential on the anode, and try to equalize the potential difference by accelerating towards that high potential. In filament-based X-ray tubes, those electrons are a result of thermionic emission of a filament, and the thermionic emission is created as a result of running a current through the filament itself, similar to a traditional Edison lightbulb. The more current running through the filament, the hotter the filament is and the more electrons are released through thermionic emission.

Filament Current Control

The filament current is tightly controlled by the power supply based on the HV and beam current demand. The higher the beam current demand, the higher the filament current runs. The higher the kV at a given beam current operating point, the lower the required filament current to achieve the beam current set point. Regulating these interdependent control loops is the job of the X-ray power supply, which generates the high voltage required to produce the demanded excitation voltage, and regulates the filament current in order to produce the demanded beam current.

In order to produce a cloud of electrons, the filament must be hot enough to overcome the work function of the filament and enter the thermionic emission region, but if it’s too hot the filament itself will sublimate and eventually fail. Because thermionic emission is exponential with temperature, even small changes of just a few thousandths of an amp in the filament can produce huge swings in the amount of electrons in the cloud, and therefore in the beam current. For most Micro X-Ray filament tubes, emission often starts at ~1.2A, and exceeding ~1.8A can cause the filament to break in a matter of seconds. For this reason, filament current control loops are generally very stable DC currents.

Because filament control loops are often quite slow as a way to preserve the life of the filament and prevent overshoot, X-ray power supplies come equipped with two important settings: filament pre-heat and filament maximum. The pre-heat holds the filament at some fixed current below the emission threshold, which helps to reduce start-up time when X-rays are demanded. The filament maximum prevents the power supply from applying more than a certain amount of current to the filament to ensure a long service life. For most Micro X-Ray tubes, 1.0A is the recommended pre-heat setting, and 1.7A is the recommended maximum current limit setting. These settings reduce turn-on time while preserving the life of the filament.

What Power Supply Should I Use?

Selecting a power supply that can provide a stable beam current, filament current, and high voltage is critical to ensuring a long service life for your X-ray source. An integrated solution like the Microbox provides all the needed control, with a simple digital interface and 24V input requirement. For stand-alone systems, Micro X-Ray is pleased to provide a variety of power supply solutions depending on your exact application requirements. Reach out today for more information.

2020 Micro X-Ray

2020 Micro X-Ray