X-Ray Sources 101: What is Focal Spot Size and Why Does it Matter?

Spot Size and Resolution

Image Quality

- Geometric Unsharpness: The quantitative term for the loss of definition in an image due to focal spot size (and other geometric factors).

- Penumbra: The partially shaded region on the edge of the shadow in an image.

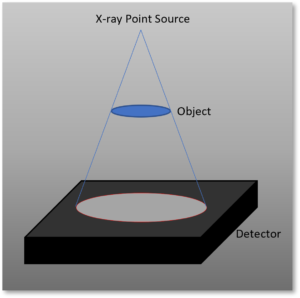

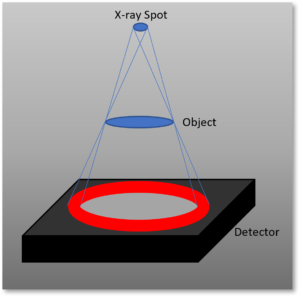

X-ray coverage on a detector shown with a X-ray point source

X-ray coverage on a detector shown with a X-ray spot of some quantifiable size

What does this mean in practice?

When selecting a spot size, the amount of geometric unsharpness that you can tolerate depends on the size of the feature you’re measuring and the size of the penumbra.

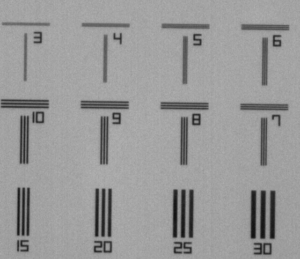

The above image is of an X-ray of a line pair gauge, taken with a Microbox with a 5μm focal spot size. The line pairs are a high density material on a low density substrate. Each grouping is a set of three lines of a certain width, spaced the same width apart. This gives us a easy, repeatable way to measure the size of resolvable details using any given X-ray source.

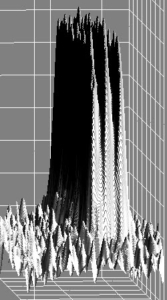

If we now zoom in on the 5µm line pair and apply a 3D visualization by assigning the grey value to the Z axis, we can easily resolve the three distinct peaks by eye; one peak for each of the three 5um width lines on the gauge. However, notice the pyramidal shape and how the features tend to blur together at the base of the shape. This is the penumbra from the 5μm spot causing geometric unsharpness that’s blurring the image, and because the lines and spaces are themselves only 5μm, we are nearing the minimum resolvable feature size of this source. Whether or not this resolution is good enough is a choice for the system designer to make.

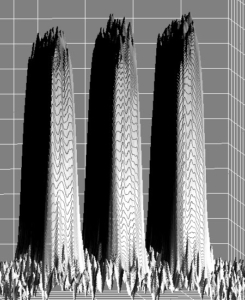

Next, we’ll zoom in on the 30µm pair from the same line pair image, and apply the same 3D visualization. In this case we can see a distinct tabletop shape to the lines, with a clear valley between them. This is because the penumbra from a 5µm spot will only blur the outer 5µm of the lines. Because the lines are 30µm wide and the space between them is 30µm wide, the line pairs are clearly resolvable and can easily be distinguished.

What size spot do you need?

Other factors affecting resolution

Let’s Talk!

Contact us today to talk about your imaging application, our Microbox source which is purpose-built for X-ray imaging, or anything else X-ray related!